The development of more stringent building codes, coupled with the growth of high-performance building programs and Home Energy Rating Systems (HERS) standards, has driven increased scrutiny on the insulation systems that comprise a building's thermal barrier.

A key factor of insulation system performance is the installation. Model building codes now include a table of insulation installation criteria—used as an inspection checklist by building officials.

In addition, the HERS industry has developed uniform guidelines for consistently grading the installation quality of building insulation. HERS Raters follow these guidelines to assign a grade of I, II, or III, with Grade I representing the highest quality. High-performance building programs, such as the ENERGY STAR® Home and DOE’s Zero Energy Ready Home require Grade I to achieve program certification.

With this emphasis on achieving a Grade I insulation installation, it is helpful to familiarize yourself with the following key considerations captured in the HERS guidelines:

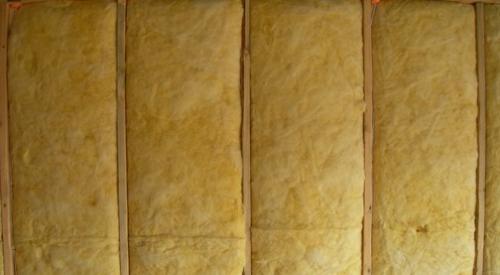

· Cavity fill and compression: To achieve a Grade I rating, each cavity should be uniformly filled side-to-side and top-to-bottom. Wall assemblies also require the insulation fills cavities front-to-back, flush with the interior face of framing members. With floor and ceiling assemblies, the insulation must fill all cavities side-to-side and end-to-end.

· No gaps or voids: Grade I installations should have no “substantial” gaps or voids in the insulation, around or behind obstructions such as blocking, bridging and electric boxes. The insulation should be split, installed and tightly fitted around wiring and other services in the cavity. It is not considered a Grade I installation if the exterior sheathing is visible from the building interior through gaps in the cavity insulation material.

· Alignment and enclosure: The insulation acting as the thermal barrier surrounding the conditioned living space should be in continual alignment with the air barrier. For wall assemblies, the cavity insulation should be enclosed on all six sides and be in substantial contact with the sheathing on at least one side (interior or exterior) of the cavity. In floor and ceiling assemblies, the insulation should be in full contact with the subfloor or ceiling material it is intended to insulate. The insulation in rim or band joists should be in substantial contact with the joist. However, the interior sheathing or enclosure material requirement is optional as the insulation does not need to be enclosed to achieve Grade I.

It is also important that all gaps, cracks, and openings at the intersection of building assemblies (ceilings, walls, and floors) and all penetrations through the framing and cracks in the framing cavities should be air sealed before the insulation is installed.

By focusing on the above key considerations, installers ensure that their jobs will pass building code inspection and receive a Grade I from HERS inspectors. This eliminates time-consuming and costly call-backs while enhancing their professional reputation with builders. More information is available at Owens Corning’s dedicated YouTube channel for a series of easy-to-follow instructional step-by-step online videos. In addition, the Owens Corning field installation guide, Achieving Grade I with Fiberglass Batts, can be found at http://www2.owenscorning.com/literature/items.asp?categoryID=6&tradeshow=.