For builders, the motivation to close on zero-punch homes is simple: Delivering defect-free homes makes customer satisfaction skyrocket, thereby increasing referrals and sales. A secondary but nonetheless important benefit is that a commitment to and execution of a zero-punch policy frees superintendents to do things other than constantly check up on trades' work. Reduced operating costs and predictable production can be attractive by-products.

So how does a builder get there? A logical start is to challenge your trade contractors to build a zero-punch home.

Construction of a zero-punch home requires every trade contractor to build it right the first time and pass builder inspection without correction items. The idea is that the trade contractors develop capabilities to prevent punch items and in turn improve the quality of every home.

| Most homeowners find more than 1.6 punch items during a typical construction process. Does this indicate that inspections are less than 80% effective or that there are more than 1,000 punch items? Neither answer should be acceptable.

|

Missing the Punch

It might surprise you to learn that zero-punch is almost impossible to achieve by adding more inspections. That certainly will not reduce costs. No matter how many inspections are performed, punch items slip through the process unless the process is changed.

A rule of thumb among quality professionals is that visual inspections uncover eight of 10 defects, so for every eight defects found, two get through to the next inspection. Other things being equal, the greater the number of defects found by an inspector, greater still is the number of defects slipping through.

Multiple inspections throughout construction don't necessarily help because with conventional inspection practices, only the first inspection evaluates the quality of the craftsman's work, and subsequent inspections look for the previous inspectors' errors. If the first inspector, the crew foreman, missed 20% of the items, according to the quality inspection rule of thumb, the next inspector is likely to catch only 80% of the ones the foreman missed. It follows, then, that the homeowners will have punch items to find when it's their turn to inspect.

| Tracking progress toward the complete zero-punch home is simple and straightforward when a milestone chart is used. For each zero-punch milestone achieved, the block on the chart is highlighted in color. The chart tracks zero-punch achievements for work crews, trades and construction phases. It is easy to see progress and the remaining milestones.

|

The only effective approach to a zero-punch home is to prevent quality problems from occurring in the first place. With first-time-through quality at every trade level, quality no longer depends on inspections.

What's in It for Me?

What is a subcontractor's motivation to decrease defects? The same as the builder's: the bottom line.

The key to getting your subs to take up your zero-punch challenge is showing them it is a business opportunity. Ask each trade what problems occur with its crew's work, and chances are the problems are always the same and never seem to go away. Now get the trade to figure out how much fixing routine problems costs by doing a cost-of-quality analysis (see equation).

Ask each contractor how many people are on the crew and what the average annual salary is. Then ask what percentage of total work time the crew spends correcting punch items. From there the contractor can multiply the percentage of time by the number of people correcting items to figure out the full-time equivalent or the number of full-time employees who could be paid with the money and time being lost correcting punch items.

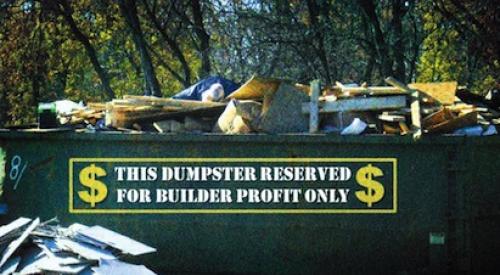

For instance, if a foreman has a crew of 10 people and finds they spend 10% of their time correcting punch items, that means one person could spend all his time just doing punch items. If that person earns the average salary - say $30,000 - the contractor is throwing away that much money a year.

The builder, of course, should do the same calculation, taking into account how much time and money are spent by foremen, superintendents and construction managers dealing with routine problems.

|

Although your contractors might keep the calculations confidential, their intense reaction to their cost of quality tells all.

They have made the connection between quality and profitability. Now they are prepared to listen to a zero-punch strategy aimed at turning quality problems into a profit opportunity.

Getting It Done

The prevention of quality problems requires the elimination of their causes. Eliminating causes might be as simple as training work crews in proper construction methods or as systematic as coming up with a means of identifying and attacking problems.

Solutions to complex problems might involve selecting new materials, redesigning construction details, reinforcing personal accountability for quality or comprehensive training programs. Several approaches may be tried before an effective solution is found. In any case, efforts to eliminate each type of punch item must be relentless.

Every solution that prevents a punch item brings a trade contractor one step closer to the zero-punch goal. As each trade progresses toward that goal, overall first-time quality gradually increases. Soon trade contractors who never achieved a zero-punch inspection will celebrate their first perfect inspection. As the effort continues, zero-punch inspections will become the norm.

The excitement builds when multiple trades reach perfect inspections on the same home, and the vision of a complete zero-punch home starts to become a reality. Keep the excitement going by setting intermediate milestones for construction phases on the way to a complete zero-punch home. Track these successes in a visual way, such as the chart at left, so everyone knows the score.

As trade contractors hit their zero-punch goals more and more often, the complete zero-punch home might seem imminent. That can be deceiving. In keeping with the laws of probability, a complete zero-punch home becomes feasible only when each trade contractor can achieve zero-punch in two of three homes. Even then, the probability of 10 trades' building a complete zero-punch home is one in 50.

The zero-punch challenge goal brings focus and teamwork to achieving a new level of quality performance. Participants quickly learn the value of inspection as an improvement tool as well as the limits of inspections for catching all punch items. They understand that zero-punch requires doing it right the first time, every time. It forces development of quality improvement skills that find effective solutions to quality problems. The effect on quality, productivity and profitability benefits everyone. The pride of accomplishing a zero-punch home is a well-earned bonus.

Ed Caldeira, principal at Caldeira Quality, can be reached by e-mail at caldeiraquality@yahoo.com.